SLIMLINE MILL BORE

![]()

Replace with helical boring!

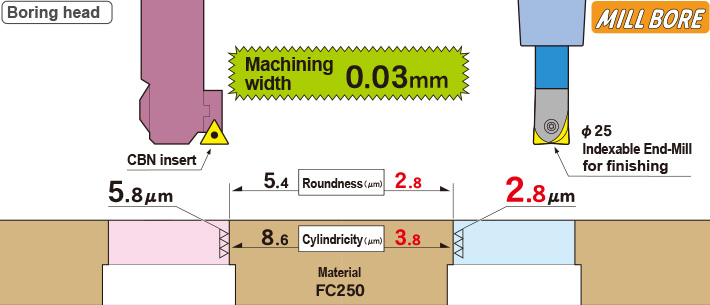

The MILL BORE is a tool holder for exchangeable cutters that combines our “SLIMLINE shrink-fit holder” with a carbide arbor. Problems associated with boring using a conventional boring head are solved with the MILL BORE because the boring process is helical.

The finished surface roughness, roundness, and cylindricity of the hole will have a higher precision than with a conventional boring head.

Solves boring application problems!

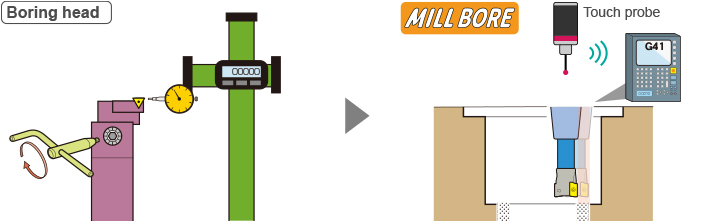

1. Reduced set-up time

|

Since dimensional adjustment is required, |

Tool diameter offset using NC control reduces the time required for manual adjustment. |

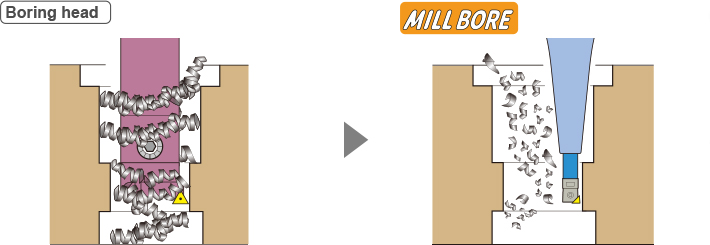

2. Chip problems are solved

|

Long, connected chips |

Milling creates only small chips |

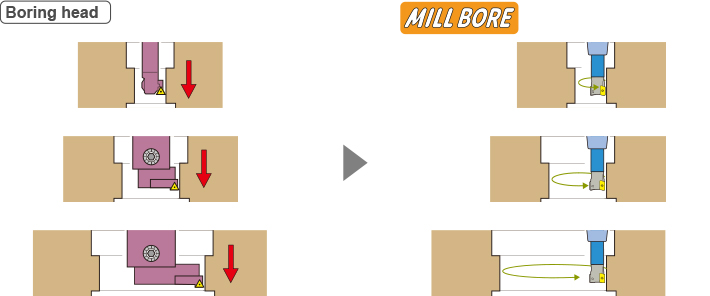

3. Reduces the number of holders

|

Need to purchase separate holders for |

1 holder can be used for boring various diameters |

4. A wide variety of tool types

|

Limited insert variations |

Compatible with a variety of indexable tools depending on the material and purpose <Manufactures> ・MOLDINO ・DIJET ・MITSUBISHI MATERIALS |

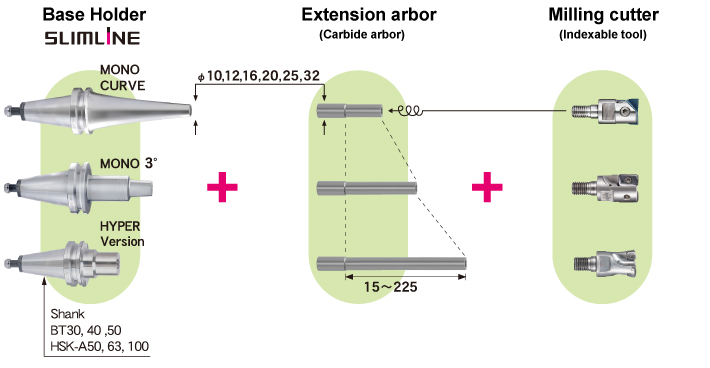

Can combined as you like

The holder and carbide arbor can be combined to ensure rigidity while avoiding interference associated with the shape of the workpiece.

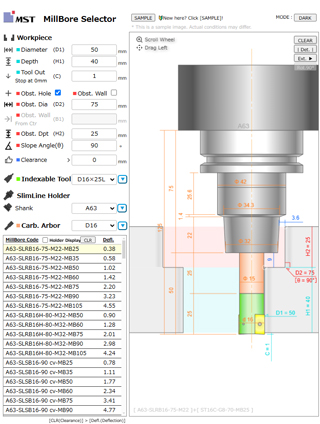

MILL BORE Selection Tool

Please use this tool to determine the optimal combination of holders and carbide arbors.

>>MILL BORE Selection Tool

※A dedicated access code is required for use. Registration is required to use the tool.

※Below screen is under development and the final specifications may be different.

Movie

Dimensions/ External drawings/ Drawing Data Download

Cutting data